Surface Treatment

Steel Surface Treatment

There are many reasons why a steel surface should be treated. From a purely aesthetic standpoint, it looks more attractive as people walk by your building. But, digging deeper, it protects the steel from scratching and peeling. It keeps the extreme weather in Australia from corroding the metal, keeping its structural integrity.

At Cedar Steel, we offer a variety of metal surface treatments. Steel is usually treated with a zinc phosphate primer, but we can deliver your metal items with several different finishes, meeting the requirements of your project.

Our Range of Steel Surface Treatments

Our standard metal treatment is the zinc phosphate primer, as per industry standard. But we know from experience that different projects require different treatments, so we also use several other methods as requested. Here are the various treatments we use at Cedar Steel and the differences between them.

Zinc Phosphate Primers

Steel beams must be protected to prevent corrosion and wear from the elements. This specially formulated primer is one of the most popular surface hardening treatments available.

Powder Coating

Electrostatic or compressed air is used in this unique method to apply a special powdered coating. This powder is then cured, forming a film over the metal. Then it is dried, creating a hard, durable finish that is extremely resistant to UV rays and rust, and cracking and peeling from the elements.

Hot Dip Galvanised Finish

Another surface treatment process for steel is the galvanised finish. This treatment offers long-lasting protection against all of Australia’s harshest climates. This method can be used for any size or shape of steelwork or metalwork, as it involves sinking the steel into a tub filled with molten zinc. This zinc is heated to temperatures of 450 °C, which then forms a protective coating around the steel. This is another popular option for surface treatment.

Hot Zinc Spray

This option doesn’t allow for quite the same protection as the galvanised steel zinc bath, but it is a popular option because it creates an extremely smooth finish on the steel. In this method, zinc is blasted onto the steel according to specs, usually between 50 and 100 microns. This is a good option for fences and railings.

Whichever method you choose, Cedar Steel will work with you to draw the specs to your requirements and meet the needs you set forth for your steel surface treatments.

Working with Cedar Steel

Cedar Steel has been a leader in the commercial steel fabrication and surface treatment industry for over 30 years. We use our knowledge and experience to provide the best service possible for our customers.

Our goal is to ensure that you get the highest quality steel materials and the best possible steel surface treatments on all of your commercial or residential fabrication projects. If you’re in the market for surface treatments on your next project, give us a call — we’ll get you a free quote.

Expertise

STRUCTURAL POST SUPPLY

QUALITY ASSURANCE

PRE-SITE ASSEMBLY

STRUCTURAL FABRICATION

DETAILED DRAWINGS

INSTALLATION

CUT-TO-SIZE

WELDING

DELIVERY

Expertise

STRUCTURAL POST SUPPLY

STRUCTURAL FABRICATION

CUT-TO-SIZE

QUALITY ASSURANCE

DETAILED DRAWINGS

WELDING

PRE-SITE ASSEMBLY

INSTALLATION

DELIVERY

Frequently Asked Questions

Steel Surface Treatment is the process of modifying the surface of steel to improve its appearance, extend its life and enhance its performance.

This process is done by creating a protective coating that will make the surface of the steel able to prevent corrosion and other forms of damage.

Surface treatment process for steel is recommended because it can extend the steel lifetime and condition as it will protect the surfaces from corrosion, scratching, peeling and extreme weather climates.

Choosing one of the methods of steel treatment will improve the water resistance of steel and upgrade the hardness and sturdiness along with making the steel look more attractive.

The most common method to treat the steel are

Zinc Phosphate Steel:

One of the most popular and recommended, this primer protects and prevents corrosion and wear from elements.

Powder Coating:

This method is done by applying a special coating that then is cured forming a film over the metal, resulting in a hard and durable finish that is very resistant to UV rays and other damages such as cracking and peeling.

Hot Dip Galvanised Steel:

Long-lasting protection against hardest weather conditions and it involves sinking the steel into a tub filled with molten zinc.

Zinc Spray Steel:

Zinc is blasted onto the steel between 50 and 100 microns creating a smooth finish, this method is highly recommended option for fences and railings.

To know what is the best type of method for your steel project, we encourage you to contact one of our professionals that can guide you through.

Cedar steel is dedicated to provide high quality results on every project of steel surface treatment, since we are the top structural steel suppliers in Sydney and throughout NSW with over 30 years of experience.

Cedar Steel is your choice if you need surface treatments, so don’t hesitate to get in touch with us to request a quote and start your next steel project with us.

We also invite you to check all the industries we work with as you need a steel specialist, we are leaders of steel structure fabrication.

Request a quote

Simply fill out the form or contact us directly on:

Structural Steel Fabrication

Expertise

Structural Steel Fabricators

Cedar Steel has worked on a wide range of projects, both big and small, and have the knowledge and expertise with over 25 years of experience in the industry to partner with your residential, commercial and industrial building endeavours.

Structural Steel Fabrication in Sydney

Work with dependable fabricators for all the structural steel supports you need for your residential, commercial and industrial projects. As experts in structural steel design, fabrication, delivery and installation, you can trust us to oversee the entire process.

Cedar Steel has worked on a wide range of projects, both big and small, and have the knowledge and expertise with over 25 years of experience in the industry to partner with your residential, commercial and industrial building endeavours.

Structural steel is one of the most versatile and widely used materials in the construction industry. The strength, durability and lightweight of this material makes it ideal for a variety of applications, from bridges and skyscrapers to smaller projects like sheds and fences. However, on top of getting down the right design and materials, hiring the right structural steel fabricators is essential in ensuring that you get the parts you require for your project, to the precise specifications of your order.

We pride ourselves on our immaculate attention to detail, high-quality workmanship and communicative customer service, so you can be confident that you’re in good hands.

About Our Approach

Structural steel fabrication is a specialised form of steel fabrication that is used to create the framework for buildings and other structures.

At Cedar Steel, we take a holistic approach to structural steel fabrication. We believe that the best way to create high-quality structural steel is to start with the best raw materials and use state-of-the-art manufacturing techniques.

We source our steel plates from reputable suppliers and use advanced computer-controlled equipment to fabricate it to precise specifications. On top of cutting, our fabricators put steel through heat and pressure in the welding process to fold and join parts together. Once complete, we then go the extra mile to protect our structural steel from corrosion by using galvanised coatings and other protective treatments.

The finished product is then shipped to the construction site, where it is bolted or welded into place. As a result of our commitment to quality, we're able to produce structural steel that meets or exceeds the strictest industry standards.

It's why we're one of the leading companies for structural steel fabrication in Sydney.

Structural Steel Fabrication: Our Process

As we comply with all the relevant Australian material and design standards in our steel fabrication services, you can trust us to look after the fabrication of steel structures.

Furthermore, our steel fabricator services is always guided by the needs of our clients: We work with you.

Working off your requirements, we draft designs with full detailed drawings of all the parts you require, erection plans, and clear shop drawings. We can also use 3D drawings for rfi’s, full-scale templates for complex layouts and isometric detail sketches of complex connections to get a full understanding before we start to shape steel, depending on what your project needs. Our metal fabricators then form different structures from pieces of steel through various types of welding that meet the brief you need for your project.

We can offer the following:

- Universal Beams

- Universal Columns

- Parallel Flange Channels

- Tapered Flange Beams

- Channels

- Squares

- Rectangular Hollow Sections

- Circular Hollow Sections

- Flat Bars

- Cleats

- Other Types of Steel Sections

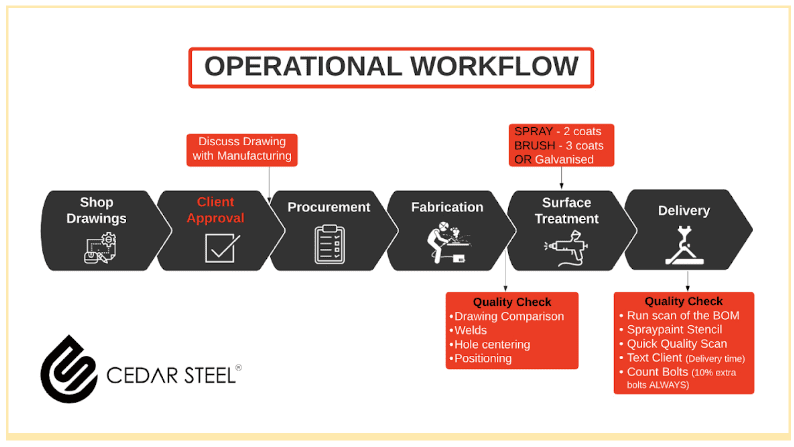

How We Work: Step-by-Step

Shop Drawings - Our draftsman engineers create shop drawings based on initial consultations with our clients. The drawings include important information that can be approved by the client/engineers before installation. Client approval - After discussing the drawings with our manufacturing team, we begin fabrication only after receiving approval from the client. Procurement - We source quality steel (mild steel and industrial steel) in Australia for each job, depending on its unique properties. Fabrication - We start fabricating your project based on the approval of the customer and drawings. We check the quality as we go. When we finish fabricating, we do a test assembly to make sure everything is how it should be. Delivery - We provide all types of surface treatments to increase the longevity and durability of your structural steel beam. Our surface treatments include, and is not limited to, Hot dip galvanising, Weather-Proof Primer, and Zinc Phosphate Priming. Surface treatment - Once our quality checks are done, we deliver the product (with the needed Nuts and Bolts) to your site address. We also provide quality installation services for various steel structures.

Why Choose Cedar Steel?

Structural steel is at the heart of what we do. Our team of structural steel fabricators work with you from start to finish, ensuring your project is delivered on time, on budget, and to the high-quality standards you expect. We have a wide range of structural steel products and services that we offer, and we’re always happy to customise our offerings to meet your specific needs.

Frequently Asked Questions

Structural Steel Detailing is the process of creating detailed drawings and specifications for the fabrication and assembly of steel structures.

Structural Steel Drafting is important because it provides information and details that will ensure that the fabrication and construction drawings of steel are accurate, helping to reduce risk over errors and reworks.

With this process we will make sure the structure is stable and lasting during and over its lifetime as we assure it is under the correct regulations.

3D Steel Detailing works in different stages, first a designer will put into a software – called Computer-Aided-Design (CAD) – the requirements and specifications of the project, this will include every element from the size of the building to the connections details.

Once this is complete, the software generates a 3D model of the structure based on the information provided, the software allows to generate 2D fabrication and erection drawings as it will detailed the information on how the steel structure should be fabricated, assembled and erected on the construction site.

3D technology offers greater accuracy, quality, more flexibility and reduces reworks and errors.

This will depend on the type of steel you need, size and complexity of the project.

In general, structural steel fabrication in Sydney is priced by the tonne, but there are also a number of other factors that can affect the final cost.

For an accurate estimate, it’s always best to discuss your project’s specific requirements with one of our Cedar Steel’s professional members and get a quote.

Cedar Steel is your best choice for a residential, industrial, or commercial steel fabrication.

We are the leading structural steel supplier in Sydney and throughout NSW, as we are experts in what we do with over 30 years of experience in the steel industry.

We are dedicated to providing flexible and personalised solutions in steel. Making every piece unique, we committed to produce all of our projects with the highest quality and under the hands of our dedicated professionals.

We invite you to get to know all the industries we work with and get in touch with us to request a quote to start your next steel project with us.

Request a quote

Simply fill out the form or contact us directly on:

Steel Installation & Erection

Structural Steel Installation & Erection Services

Cedar Steel has the capability to conduct large structural steel erection jobs. For large-scale installation projects of steel components and roofing materials, look no further than our steel frame installers.

Steel Installation & Erection

As masters of steel fabrication for commercial and industrial sectors, we employ a talented team of steel erectors to provide all clients with a streamlined and controlled steel installation service. Believe us when we say that installing metal roofing is our specialty.

Offering experience, attention to detail and strict quality control measures, we ensure a confident process from initial construction right through to the erection of a steel building.

Rest assured, Cedar Steel’s qualified team of steel frame manufacturers and erectors deliver excellent results across multiple areas of steel installation.

Our experts are adept in installing steel components into any position that you require. We’ll arrange for the delivery and erection of all steel projects, big and small. For on-site steel installation projects, we provide flexibility using our own dedicated access equipment and cranes.

Backed by years or experience, we aim to always meet and exceed all of our client’s requirements and expectations.

Erecting structural steelwork: Our process

Designing for construction

Successful structural steel installation and erection begins long before the steelwork arrives on-site from the fabrication workshop. Before installation commences, the ‘buildability’ of your internal steel structure is influenced by client and expert decisions made during the design process. At Cedar Steel, our team “designs for construction”- an important design objective that facilitates better safety outcomes, construction project efficiency and looking into potentials for prefabrication.

Design factors that we consider include:

- Repetition and standardisation- refers to the repetition of the same structural components and standard details for connections.

- Achievable tolerances- If ‘tight’ tolerances are specified in the brief (i.e. more restrictive than Class 1 in AS/NZS 5131), we can consider the implementation of special controls and engineered details.

- Frame type- We look into your primary choice of frame options. Options include braced frames and continuous frames.

- Floor systems- Your choice of floor system for multi-story projects and frames will influence the erection sequence as it determines the part-erected structure's stability.

Erection planning

Our experts begin steel erection planning at the very beginning of the installation process. We consider the construction sequence and design factors affecting site practice in terms of a typical erection plant. We consider three planning factors which include:

- Practical erection sequence: We look into the location of both temporary and permanent bracing systems and other means of maintaining structural balance.

- Simplicity of assembly: How easily can we assemble frame connections across all steel components.

- Logical trade sequences: This affects the development of the master contract as your pre-tender plan turns into the final construction plan.

The fabrication process

The procedure of fabricating steelwork parts that will, when put and connected together, create a complete frame. The steel frame generally comprises readily available components from our steel fabricators and steel stockholders. This includes additional manufacturing elements such as adding protective coatings and bolts.

Installation & connecting the components together

The erection of structural steel usually consists of assembling steel components into a sturdy frame.

Components are lifted and placed into position before they are firmly connected together. This is achieved through bolting however, our steel erectors can also bond frames together via on-site welding depending on your requirements.

Prior to bolting, we ensure that the assembled frame is aligned within tolerance expectations as defined in our quality assurance standards. Once your steel frame has been completed, we hand it over for further construction work. This can include adding external cladding, electrical fittings and internal flooring.

Whether you require assistance installing metal roofing panels, new floor joists and timber frames to high quality light gauge steel frames, we tailor our services to every client we work with. No matter the size of your construction site, our experienced team of steel installers combine both careful planning and innovative technology to guarantee outstanding structural results.

At Cedar Steel, we take great pride in our top-of-the-line structural steel installation methods and equipment. Our process covers end-to-end services including construction, installation, alteration, repair, maintenance, demolition and dismantling.

From T-bar beams to metal panels, structural steel is an integral part to many building projects. The results of a high quality steel erection is representative of a building’s structural core. To guarantee outstanding results in logistically complicated construction sites, we take additional care in every step of the installation process, and drive it towards completion.

About our approach

Why Choose Cedar Steel

We aim to tick off three primary goals when erecting structural steel- timing, safety and accuracy. Not only are our specialists capable of meeting deadlines, our staff stand by maintaining accuracy no matter the size and scope of the project. Feel rest assured that our experts pay special attention to minimising risk exposure, and ensuring that our processes are safe, efficient and innovative.

Request a quote

Simply fill out the form or contact us directly on:

Steel Beams

Structural Steel Beams

Structural steel beams have been employed by engineers to accomplish things that were previously thought impossible such as constructing vast buildings and bridges that continue to withstand the test of time for hundreds of years.

Steel Beams in Sydney

As Sydney’s leading fabricator and steel beam supplier, Cedar Steel stands by quality and versatility. Which is why we manufacture, supply and install structural steel solutions for the best of Sydney’s residential, industrial and commercial building contractors, engineers and project managers. It is the people within the development and construction industry that have relied on our team to provide steel beam stocks for government, commercial and residential requirements.

From non-fabricated solutions all the way to wide flange, rebar and I-beams, we can fabricate and supply any beam style to suit the unique building requirements of our clients. We can even provide many more fabricated extras if requested.

All steel beams in Sydney are supplied finished in a zinc phosphate primer as per industry standard, unless otherwise requested by the client.

For more information regarding our end-to-end services, don’t hesitate to contact our team.

Types of steel beams

Australia is undeniably a dominant force in the metal mining industry and remains a world leader in the export of iron ore, lead, zinc and so much more. As a result, structural steel in Sydney is not only plentiful but can be fabricated in a range of options. We can offer the following:

- Universal Beams: We provide a range of universal beams including ‘Standard’ (section lengths from 9m to 20m), or ‘Heavy’ (460 mm, 540mm and 610mm). Non-standard lengths are also available on request. Ideal for civil construction, residential buildings to general manufacturing applications.

- Universal Columns: Similar to universal beams, universal columns can be utilised for many construction projects for structural support. At Cedar Steel, we can supply both L or H shapes and are available in five basic sizes, flange depths and thickness. Our light steel columns range from 100mm to 200mm and heavy steel columns ranging from 250mm to 310mm. Also ideal for residential buildings, civil construction and general manufacturing applications.

- Channels: The following structural beams boast a C-shaped cross section, and feature top and bottom flanges with a web connecting them. Channels are cost-effective solutions for either short to medium-span structures. Originally designed to support bridges, they are now popular for more modern building applications. At Cedar Steel, we can supply a range of custom structural channels to meet your engineering and construction needs.

- Structural Angles: Any steel bar that features an L-shaped cross section or boasts a 90 degree angle. The following products are ideal for all manners of indoor and outdoor structural applications, repairs and general fabrication. This structural solution can boast equal-sized flanges or custom depending on your building project requirements.

- Hollow Steel Section (HSS): HSS refers to a metal profile featuring a tubular (hollow) cross section. Such steel beams can be rectangular, square, circular or elliptical in shape. For engineering purposes, HSS sections deliver greater flexibility in the use of more extreme strength-to-weight ratio than conventional structural steel products.

No matter the shape, size or implementation of your next construction project, steel beams offer many advantages to almost any building structure.

The building material is a predominant feature in contemporary architecture due to its aesthetic appeal, durability, and adaptability. They are also recognised as the most sustainable building material in the construction industry.

Other key advantages include:

Longevity

Australian weather is notorious for its extreme weather conditions. Steel beams can withstand the wear and tear caused by floods and hurricanes, keeping your building structures safe and secure. Best of all, steel is over 80% recycled in the manufacturing process without impacting quality.

Adaptability

Structural steel beams are preferred by builders, engineers and architects throughout Sydney due to their adaptability to designing structures. Steel maximises the space of a building structure, requiring less room than other materials such as concrete. This way, internal structures can be altered or upgraded for change of use without affecting the integrity.

Aesthetics

Unlike other materials like concrete, structural steel is praised for the aesthetic appeal it offers. Its flexibility allows the steel to be welded into different shapes and sizes, creating dramatic facades that can last years. As it is both strong and lightweight, it is favoured within the construction industry.

Why Use Structural Steel Beams?

Why Cedar Steel

Backed by 30+ years of industry experience, Cedar Steel has since grown to become a household name as Sydney and regional NSW’s leading steel beam provider for commercial, residential and industrial sectors. We endeavour to wear that badge with pride with our comprehensive steel products, design and fabrication services.

No matter the size and scope of your upcoming building project, or the service that you require, feel rest assured that you will be working with trustworthy and experienced experts in the field. We can offer premium quality steel beams that best meet your requirements.

Request a quote

Simply fill out the form or contact us directly on:

About Us | Structural Steel Fabrication Australia

About Us

Masters in Structural Steel Fabrication and Supply for Residential, Commercial and Industrial Construction.

Led by 30+ years of industry experience

Cedar Steel is your local steel supply specialist in New South Wales, providing high-quality steel posts for residential properties and structural steel beams throughout Greater Sydney and NSW.

Family owned and operated, Cedar Steel is led by 30+ years of industry experience. We don’t mean it lightly when we say we know the structural steel industry inside and out.

Capabilities

- 48-hour delivery (Residential)

- Expert shop drawings

- Structural Beams

- Structural Posts

- Steel Fabrication

Built On Trust

We guarantee excellent results across various structural steel fabrication services, from steel drafting, surface treatment, right through to delivery. We’ll even throw in the nuts and bolts during the delivery stage. Every job has its unique quirks, and our specialists pride themselves on offering flexible, personalised solutions for residential steel.

Whether you’re drawing up plans for a home extension or thinking of constructing a granny flat to increase your property value, Cedar Steel has the expertise and skill to complete any structural steel fabrication project.

We are proud to claim that we are NSW’s Carpenters and Builders preferred choice for procuring quality steel products, and maintain long-term relationships with our clients, even for short-term profits.

What’s special about Cedar Steel?

Cedar steel is located within the heart of Sydney’s thriving construction area (Western Sydney). As a result, clients can access quality structural steel products and accessories 24/7. With 30+ years of industry experience, customer satisfaction and transparency is of the utmost importance. As a result, we do our best to respond to client concerns from decreased stock, product enquiries in a timely and efficient manner. Our number one priority is to ensure you receive the highest quality customer service and privacy.

Our contact number is open 24 hours 7 days a week.

Don’t hesitate to contact us 02 8106 0000

As well as supplying and manufacturing all types of structural steel components for Residential, Commercial and Industrial Properties, we also offer tailored CARD drafting for all engineering and architectural blueprints.

We turn your plans into shop drawings for approval, cut the steel and fabricate the steel beams ourselves, and apply surface treatment and deliver, ready to be used and installed by your construction team.

Our full services:

- On site job measuring

- In-house drafting

- Supply & fabrication of structural steelwork

- On-time delivery

The Preferred Choice

We supply structural beams for a variety of residential projects from granny flats, multi-level apartments, new builds to rescue projects. No matter how challenging your project, we can fabricate the following top-tier residential steel products, including:

- Structural steel beams and columns

- Structural steel for commercial portals and structures

- Structural steel piles

- Custom doors, stairs and gates

- Structural steel for any building application- lintels, tbars and posts for pergolas and carports

For more information about our projects, check our social media pages.

Request a quote

Simply fill out the form or contact us directly on:

Structural Steel Supply & Fabrication

Expertise

Structural Steel Supply Sydney

As the preferred supplier for residential steel, we strive to provide our clients with service and results that exceed their expectations, and value for money. If you’re ready to work with us, contact us today for a free consultation.

Structural Steel Supplier in Sydney

Cedar Steel stands out when it comes to structural steel supply in Sydney and NSW. We have extensive knowledge of our area of expertise thanks to more than three decades of bringing materials to residential, commercial, and industrial projects.

We always strive to deliver the exact structural steel supplies Sydney construction companies need to get the job done, regardless of the size of the project or the amount required. Our focus on quality has helped us exceed the expectations of our diverse list of clients.

You can see our attention to quality and superior service for yourself without making any commitments. We are happy to learn the details of your project and provide a detailed free estimate.

What You Can Expect from Us

At Cedar Steel, we do more than bring structural steel supplies to your worksite. Unlike many structural steel suppliers, we deliver end-to-end services for small home projects, large commercial constructions, and everything in between. Our goal is always to provide every customer with the best overall value with a combination of products and services that other NSW structural steel suppliers cannot match.

Our Approach

Whether you need a commercial or residential steel supplier, Cedar Steel can deliver. We use the same approach whether we are supplying a residential project or a commercial development. Every step of the process is equally important in achieving the desired result. We cover the entire supply chain, from selecting the best raw materials to using the right techniques to fabricate the necessary steel components for each project.

Not only does this approach deliver the right shapes and sizes, but it ensures each piece is manufactured to your quality and strength needs.

How can we consistently deliver steel that exceeds expectations? In addition to access to superior materials, we work with engineers, welders, and other tradespeople with the skills and experience to deliver steel frames and other types of steel fabrication that fit the project’s specifications exactly. We take the time to understand how our products will fit into your overall plans, so we can account for every variable during the production and design process.

We have perfected our supply chain and fabrication processes over the past 30 years. This means that once you accept our bid, we will put our team into action and deliver your steel components on time and within your budget.

Our Services

As an experienced industrial steel supplier, we know that details matter. Each project begins with our experts learning the fine points of your project and taking measurements of the site to ensure complete accuracy.

We proceed to draft plans, create necessary drawings, and even produce 3D models that can guide our specialists as they fabricate the components according to your needs and measurements. The plans can include specific details, such as placing holes or openings in the steel frames for complex industrial applications.

The next step is the actual fabrication from quality raw materials. Because of our careful planning, measurements, and design process, the engineers, welders, and other specialists can create the components exactly as required to fit with the other elements of the structure.

Delivery and Installation

We can also deliver the finished steel components to your worksite in Sydney or elsewhere in NSW. We start this process by packaging the steel for safe and efficient transport and straightforward assembly once it arrives on-site.

In addition to handling the delivery process, we can oversee the installation process, if needed, with our experts coming to your site to ensure proper placement and structural security. Since we offer comprehensive upfront pricing, you will know ahead of time what the overall cost of the project, including any delivery or installation steps, will be before we start.

Reach Out Today for More Information

Cedar Steel is your best choice for a residential, industrial, or commercial steel supplier in Sydney and throughout NSW. We can provide you with superior quality for any project. You can start the process with a free, no-commitment quote for our products and services. Contact Us today to learn more.

Request a quote

Simply fill out the form or contact us directly on:

Services

Expertise

Steel Fabrication Services

Cedar Steel offers complete, comprehensive and cost-effective structural steel beams, design and fabrication solutions to provide quality service to residential, commercial and industrial sectors throughout Sydney, and regional NSW.

Structural Steel Fabrication Services

At Cedar Steel, we plan, design, weld, and supply ready-made and custom steel products for industrial, commercial, and residential projects. As a leading steel supplier, contractors rely on our high-quality steel to complete their most complex building projects in New South Wales, Australia.

We’ve partnered with contractors in several different industries, building structures such as schools, shopping centres, factories, rental houses, and many others. For all our clients’ fabrication inquiries, we provide a detailed quotation and a plan indicating the project breakdown with predicted costs.

We offer the following industrial steel services:

1. Steel detailing, Drafting, and Design

Structural steel drafting and design involves a complex process of creating a design that matches the builder’s exact specifications. We produce a range of designs, such as beams, stairs, columns, and braces, that can be used for construction projects.

Structural steel detailing and drafting requires advanced technological software that enables 3D designs to be produced faster. The software works wonders because it allows the project to be built virtually, and we can see how well it fits our needs. It also makes complex projects easier because we can see the details before manufacturing.

Once we partner with a client, our engineers plan the project’s details, including cost, safety, performance, and adherence to the building codes.

Industrial Steel Services

2. Structural Steel Fabrication

We work on small and large projects, from staircases to bridges, skyscrapers, wind turbines, and pipelines.

We choose solid and durable materials for our clients and mould designs to their desired shapes and sizes. This ensures our structural steel fabrication and steel erection processes are top-notch.

We get our steel from reputable suppliers and use advanced technological equipment to fabricate the steel into desired forms. Here is our steel fabrication process:

- Client consultation – Our engineers consult with the client to get shop drawings for the desired steel fabrication designs.

- Client approval – After consultation, the final drawing copy is sent to the client for approval.

- Procurement – Only after the client approves the final drawings will the materials be procured. We get our steel from trusted sources in Australia.

- Fabrication – Steel fabrication begins after the procured materials arrive at the company.

- Delivery – After all your designs are fabricated and ready, we deliver them to your site.

3. Structural Steel Supply and Installation

Cedar Steel provides structural steel supply and installation to our client’s job sites. We have invested in the proper equipment to make structural steel installation work easier, safer, and faster. We partner with contractors directly to supply and deliver steel fabrications for easy installation. Client satisfaction is our pride and happiness.

Industrial Steel Services

4. Steel Delivery Services

Cedar Steel is a well-coordinated company that offers on-site supply and steel delivery of building structures. We have adapted our structural steel delivery services to reduce delays and minimise risk factors.

- Thorough preparation – Steel delivery is easy with careful preparation. We assemble all our supplies before delivery time to avoid making mistakes that can take us back and forth.

- On-site coordination – Time is essential; we don’t want to keep people waiting on-site. Therefore, we ensure communication between the fabricators and erectors to make deliveries easy.

- Reduced disruptions at the delivery time – Steel requires heavy lifting cranes to offload the product. It’s crucial to restrict movements on the site to give the cranes space to work safely, preventing job site accidents.

5. Steel Surface Treatments

To make your steel surfaces look more attractive, we at Cedar Steel finish our structural steel fabrication with zinc phosphate premier. However, you can select steel surface treatment finishing items of your choice, such as powder coating, hot dip galvanisation, and hot zinc spray.

Contact Us

Cedar Steel has been providing industrial steel fabrication services for more than 30 years in New South Wales, Australia. We produce a wide range of quality steel fabrications, designs, and models.

We work with individuals and contractors to ensure the success of various projects. Do not hesitate to contact us if you need industrial steel fabrication for your project. We will be happy to work with you. You can also request a quotation for free from our website.

Expertise

STRUCTURAL POST SUPPLY

QUALITY ASSURANCE

PRE-SITE ASSEMBLY

STRUCTURAL FABRICATION

DETAILED DRAWINGS

INSTALLATION

CUT-TO-SIZE

WELDING

DELIVERY

Expertise

STRUCTURAL POST SUPPLY

STRUCTURAL FABRICATION

CUT-TO-SIZE

QUALITY ASSURANCE

DETAILED DRAWINGS

WELDING

PRE-SITE ASSEMBLY

INSTALLATION

DELIVERY

Request a quote

Simply fill out the form or contact us directly on: