Structural Steel Fabrication in Sydney

Work with dependable fabricators for all the structural steel supports you need for your residential, commercial and industrial projects. As experts in structural steel design, fabrication, delivery and installation, you can trust us to oversee the entire process.

Cedar Steel has worked on a wide range of projects, both big and small, and have the knowledge and expertise with over 25 years of experience in the industry to partner with your residential, commercial and industrial building endeavours.

Structural steel is one of the most versatile and widely used materials in the construction industry. The strength, durability and lightweight of this material makes it ideal for a variety of applications, from bridges and skyscrapers to smaller projects like sheds and fences. However, on top of getting down the right design and materials, hiring the right structural steel fabricators is essential in ensuring that you get the parts you require for your project, to the precise specifications of your order.

We pride ourselves on our immaculate attention to detail, high-quality workmanship and communicative customer service, so you can be confident that you’re in good hands.

About Our Approach

Structural steel fabrication is a specialised form of steel fabrication that is used to create the framework for buildings and other structures.

At Cedar Steel, we take a holistic approach to structural steel fabrication. We believe that the best way to create high-quality structural steel is to start with the best raw materials and use state-of-the-art manufacturing techniques.

We source our steel plates from reputable suppliers and use advanced computer-controlled equipment to fabricate it to precise specifications. On top of cutting, our fabricators put steel through heat and pressure in the welding process to fold and join parts together. Once complete, we then go the extra mile to protect our structural steel from corrosion by using galvanised coatings and other protective treatments.

The finished product is then shipped to the construction site, where it is bolted or welded into place. As a result of our commitment to quality, we're able to produce structural steel that meets or exceeds the strictest industry standards.

It's why we're one of the leading companies for structural steel fabrication in Sydney.

Structural Steel Fabrication: Our Process

As we comply with all the relevant Australian material and design standards in our steel fabrication services, you can trust us to look after the fabrication of steel structures. Furthermore, our steel fabricator services is always guided by the needs of our clients: We work with you. Working off your requirements, we draft designs with full detailed drawings of all the parts you require, erection plans, and clear shop drawings. We can also use 3D drawings for rfi’s, full-scale templates for complex layouts and isometric detail sketches of complex connections to get a full understanding before we start to shape steel, depending on what your project needs. Our metal fabricators then form different structures from pieces of steel through various types of welding that meet the brief you need for your project. We can offer the following:

- Universal Beams

- Universal Columns

- Parallel Flange Channels

- Tapered Flange Beams

- Channels

- Squares

- Rectangular Hollow Sections

- Circular Hollow Sections

- Flat Bars

- Cleats

- Other Types of Steel Sections

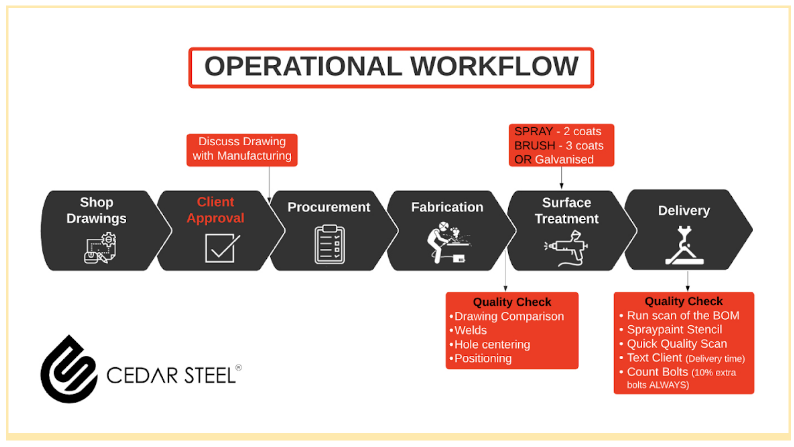

How We Work: Step-by-Step

Shop Drawings - Our draftsman engineers create shop drawings based on initial consultations with our clients. The drawings include important information that can be approved by the client/engineers before installation. Client approval - After discussing the drawings with our manufacturing team, we begin fabrication only after receiving approval from the client. Procurement - We source quality steel (mild steel and industrial steel) in Australia for each job, depending on its unique properties. Fabrication - We start fabricating your project based on the approval of the customer and drawings. We check the quality as we go. When we finish fabricating, we do a test assembly to make sure everything is how it should be. Delivery - We provide all types of surface treatments to increase the longevity and durability of your structural steel beam. Our surface treatments include, and is not limited to, Hot dip galvanising, Weather-Proof Primer, and Zinc Phosphate Priming. Surface treatment - Once our quality checks are done, we deliver the product (with the needed Nuts and Bolts) to your site address. We also provide quality installation services for various steel structures.

Why Choose Cedar Steel?

Structural steel is at the heart of what we do. Our team of structural steel fabricators work with you from start to finish, ensuring your project is delivered on time, on budget, and to the high-quality standards you expect. We have a wide range of structural steel products and services that we offer, and we’re always happy to customise our offerings to meet your specific needs.

Frequently Asked Questions

Structural Steel Detailing is the process of creating detailed drawings and specifications for the fabrication and assembly of steel structures.

Structural Steel Drafting is important because it provides information and details that will ensure that the fabrication and construction drawings of steel are accurate, helping to reduce risk over errors and reworks.

With this process we will make sure the structure is stable and lasting during and over its lifetime as we assure it is under the correct regulations.

3D Steel Detailing works in different stages, first a designer will put into a software – called Computer-Aided-Design (CAD) – the requirements and specifications of the project, this will include every element from the size of the building to the connections details.

Once this is complete, the software generates a 3D model of the structure based on the information provided, the software allows to generate 2D fabrication and erection drawings as it will detailed the information on how the steel structure should be fabricated, assembled and erected on the construction site.

3D technology offers greater accuracy, quality, more flexibility and reduces reworks and errors.

This will depend on the type of steel you need, size and complexity of the project.

In general, structural steel fabrication in Sydney is priced by the tonne, but there are also a number of other factors that can affect the final cost.

For an accurate estimate, it’s always best to discuss your project’s specific requirements with one of our Cedar Steel’s professional members and get a quote.

Cedar Steel is your best choice for a residential, industrial, or commercial steel fabrication.

We are the leading structural steel supplier in Sydney and throughout NSW, as we are experts in what we do with over 30 years of experience in the steel industry.

We are dedicated to providing flexible and personalised solutions in steel. Making every piece unique, we committed to produce all of our projects with the highest quality and under the hands of our dedicated professionals.

We invite you to get to know all the industries we work with and get in touch with us to request a quote to start your next steel project with us.

Request a quote

Simply fill out the form or contact us directly on: