Mezzanine Floor

Expertise

Mezzanine Floor Builders Sydney

A mezzanine floor is an intermediate floor installed between the main floors of a building, creating additional usable space without the need for extensive construction. These floors are ideal for maximising residential, commercial, and industrial space. Our specialisation in structural steel and fabrication services ensures that your mezzanine floors are robust, durable, and tailored to your specific needs.

Why Choose Cedar Steel for Mezzanine Floor Construction?

Cedar Steel is renowned for its expertise and experience in mezzanine floor construction. Our team of skilled professionals ensures that each project is completed with the highest quality and durability standards. By choosing Cedar Steel, you benefit from:

- Expertise in Steel Mezzanine Floor Construction: We use premium-grade steel and other materials to ensure the longevity and strength of your mezzanine floors.

- Customised Solutions: Every project is tailored to meet your specific needs, ensuring optimal use of space and functionality.

- Efficient Mezzanine Installation: Our streamlined construction process minimises disruption to your daily operations, delivering quick and efficient results.

Expert Mezzanine Floor Builders in Sydney

At Cedar Steel, we pride ourselves on being Sydney’s go-to mezzanine floor builders. Our team has extensive experience in mezzanine construction, offering a range of services that include:

- Design and Planning: We work closely with you to design a mezzanine floor that meets your requirements and adheres to all safety regulations.

- Fabrication and Installation: Utilising the latest technology and high-quality materials, we fabricate and install mezzanine floors that are both durable and aesthetically pleasing.

- Maintenance and Support: We provide ongoing support and maintenance to ensure your mezzanine floor remains in excellent condition.

Comprehensive Mezzanine Installation Services

Our mezzanine installation services are comprehensive, covering every aspect of the construction process. From initial consultation to final inspection, Cedar Steel ensures that your mezzanine floor project is executed flawlessly. Our services include:

Site Assessment

Site Assessment

We conduct a thorough site assessment to determine the best approach for your mezzanine floor installation.

Steel Mezzanine Floor Systems

Steel Mezzanine Floor Systems

Our steel mezzanine floor systems are designed for maximum strength and stability, providing a safe and reliable solution for your space.

Custom Fabrication

Custom Fabrication

Each mezzanine floor is custom-fabricated to meet your needs, ensuring a perfect fit and finish.

Benefits and Applications of Mezzanine Floors

Mezzanine floors offer numerous benefits and can be used in a variety of applications:

- Increased Space: Maximise your available space without the need for significant renovations.

- Versatility: Ideal for office spaces, storage, retail, and more.

- Cost-Effective: A cost-efficient solution to expand your usable area.

FAQs

Australia’s standard mezzanine floor height varies but typically ranges between 2.1 to 3 meters, depending on the specific requirements and building regulations.

A mezzanine floor provides additional space within an existing structure, making it ideal for storage, office space, or retail areas.

Requirements for mezzanine floors in Sydney include compliance with local building codes, proper load-bearing capacity, and adequate headroom clearance.

Mezzanine floors must comply with local building codes and safety regulations, including fire safety, structural integrity, and accessibility requirements.

Get Started with Expert Mezzanine Floor Builders Today

Ready to transform your space with a mezzanine floor? Contact Cedar Steel, Sydney’s leading mezzanine floor builders, for more information or to request a quote. Our team is here to provide you with exceptional service and high-quality results. Call us now to discuss your project and discover how our mezzanine installation services can benefit you.

Request a quote

Simply fill out the form or contact us directly on:

Structural Steel Welding Services In Sydney

Expertise

Structural Steel Welding Services In Sydney

Cedar Steel offers top-notch structural steel welding services in Sydney. With years of experience and a team of skilled professionals, we specialise in providing exceptional structural welding services tailored to our client's unique needs.

The Importance of Structural Steel Welding in Construction

Structural steel welding creates solid, reliable frameworks supporting various structures. Our team at Cedar Steel is committed to delivering structural welding services that meet the stringent Australian standards, ensuring your projects are safe and long-lasting.

Why Choose Cedar Steel for Structural Steel Welding?

Choosing Cedar Steel means opting for quality, reliability, and expertise. Here’s why we stand out among structural steel welding companies:

- Experienced Team: Our welders are highly trained and certified, ensuring precision and safety in every project. Each team member has extensive experience handling welding projects, ensuring your structures are built to last.

- Advanced Technology: We utilise state-of-the-art equipment to deliver superior results. Our advanced welding technology allows us to perform intricate tasks accurately and efficiently.

- Commitment to Quality: We adhere to the highest industry standards, guaranteeing the durability and strength of our welded structures. Our rigorous quality control processes ensure that every weld meets the strictest safety and performance criteria.

- Customer-Centric Approach: We prioritise client satisfaction, offering customised solutions and exceptional service. Our team works closely with clients to understand their needs and provide tailored welding solutions that meet their requirements.

For more information, visit our services page to learn about our structural steel capabilities.

Our Structural Steel Welding Services

We provide a comprehensive range of structural welding services to cater to various project requirements.

Custom Structural Steel Welding

We offer tailored welding solutions designed to meet the specific requirements of your unique projects. Whether a complex architectural design or a specialised industrial application, our custom welding services ensure precision and quality.

Structural Beam Welding

Our team specialises in welding structural beams, and we ensure that every beam is perfectly welded, providing the necessary strength and stability for your construction projects. This service is crucial for building solid frameworks in commercial and residential buildings.

Heavy Structural Welding

Handling large-scale projects with precision and expertise, our heavy structural welding services are designed for industrial applications and significant infrastructure projects. We have the capacity and experience to manage the demands of heavy structural welding, ensuring robust and durable results.

Fabrication Welding

We offer seamless project execution that combines both welding and steel fabrication processes. This service ensures that your steel components are fabricated and welded to exact specifications, providing a cohesive and high-quality end product.

Industries We Serve

Cedar Steel proudly serves various industries, including residential, commercial & industrial development. Our expertise in structural steel welding makes us a trusted partner for projects of all sizes.

Visit our Projects page to see the range of projects we have completed and understand why Cedar Steel is the preferred choice for structural steel welding in Sydney.

Elevate Your Project with Expert Structural Steel Welding

Cedar Steel is committed to delivering exceptional structural steel welding services that meet your project’s unique needs. Our team of experienced welders and advanced technology ensure that every weld is performed to the highest quality and safety standards.

Contact us today for more information about our services or to discuss your project requirements.

FAQs

What is Structural Steel Welding?

Structural steel welding joins steel components to create a strong and durable structure. It is commonly used in construction and engineering projects.

Depending on the project’s specific requirements, various welding methods can be used for structural steel, including MIG, TIG, and arc welding.

The Australian standard for structural steel welding is AS/NZS 1554.1, which outlines the requirements for welding steel structures to ensure safety and quality.

Expertise

STRUCTURAL POST SUPPLY

QUALITY ASSURANCE

PRE-SITE ASSEMBLY

STRUCTURAL FABRICATION

DETAILED DRAWINGS

INSTALLATION

CUT-TO-SIZE

WELDING

DELIVERY

Expertise

STRUCTURAL POST SUPPLY

STRUCTURAL FABRICATION

CUT-TO-SIZE

QUALITY ASSURANCE

DETAILED DRAWINGS

WELDING

PRE-SITE ASSEMBLY

INSTALLATION

DELIVERY

Request a quote

Simply fill out the form or contact us directly on:

Welded Columns

Expertise

Welded Columns

As industry specialists, we understand the crucial role that welded columns play in ensuring the structural integrity of your projects. Let's delve into the intricacies of welded columns and discover why choosing the right size and quality is paramount.

Understanding Welded Column Sizes

In the realm of construction, precision is key. Our welded columns come in a variety of sizes, meticulously crafted to meet the diverse needs of your projects. From small-scale developments to large industrial complexes, we have the perfect fit for every application. Explore our range of welded column sizes to find the ideal match for your specific requirements.

The Art of Column Welding

Craftsmanship is at the heart of what we do. Our welding experts utilise state-of-the-art techniques to ensure the highest quality welded columns. Every weld is a testament to our commitment to excellence, providing you with columns that stand the test of time. Discover the artistry behind our column welding process and experience the strength that lasts.

Why Choose Cedar Steel?

Unparalleled Expertise

With years of experience in the industry, Cedar Steel stands as a beacon of expertise. Our team of professionals understands the nuances of construction, and we bring that knowledge to every welded column we produce. Trust us to be your reliable partner in building success.

Comprehensive Steel Products

At Cedar Steel, we offer more than just welded columns. Explore our comprehensive range of steel products, including beams, angles, channels, and more. We are your one-stop solution for all your steel needs.

Seamless Communication

Your satisfaction is our priority. We believe in open and clear communication throughout every project. Explore our services and get in touch with us to discuss how we can contribute to the success of your construction endeavours.

Elevate Your Projects with Cedar Steel

In the world of construction, strength is non-negotiable. Choose Cedar Steel for welded columns that not only meet but exceed industry standards. Elevate your projects with the backbone of strength—choose Cedar Steel.

Contact us today to discuss your specific requirements and let us be the foundation of your success.

Welded Columns FAQs

Welded columns are structural elements crafted by welding together steel components to form a vertical support structure. These columns play a crucial role in providing strength and stability to various construction projects.

Cedar Steel stands out for its unparalleled expertise, commitment to quality, and comprehensive range of steel products. Our welded columns are crafted with precision and undergo rigorous quality checks to ensure they meet and exceed industry standards.

Yes, we understand that each project has unique requirements. We offer customisation options for welded columns to ensure they align perfectly with your project specifications. Contact our experts to discuss your customisation needs and see which of our services can best suit you!

Request a quote

Simply fill out the form or contact us directly on:

Welded Beams

Expertise

Welded Beams

Looking for a viable solution that offers amazing support as well as a strong sense of reliability? Then you don’t have to seek any further than welded steel beams! Crafted from a web and two flanges seamlessly merged through a deep penetration filet weld, these beams are engineered to withstand tremendous weights. In fact, a welded beam boasts up to 20% more strength than its standard counterparts.

Why You Should Opt For Column Welding

Welded beams share some of the same advantages as steel beams, like;

- Cost-effective nature

- Timber may seem cheaper, but a steel beam will last longer, is more versatile – making it much more cost-effective in the long-run

- Fire resistant

- As it is a non-combustible material, it will not change integrally because of fires

- Sustainability

- 100% recyclable

- Beams usually consist of up to 25% of recycled material and is known as one of the easiest materials to reuse

- Durability

- Australia has turbulent weather, and you need materials that suit that!

- Steel has a resistance to wear and tear from our unrelenting environment

- Enjoy pristine estate regardless of the weather

- Decreased Weight

- In comparison to concrete, steel is much lighter thanks to its higher strength and stiff nature

- Lightness brings about a reduced overall weigh on foundations and bettered ground condition performance

There are additional benefits that welded beams provide;

- Availability in many sizes

- Exceeds the Australian and New Zealand standards minimum requirement of AS/NZS 3679.2

- Heavy duty

- 20% stronger, improved strength-to-weight ratios

- Pre-heating is NOT required for welding

- Faster to use because they’re prefabricated

Be sure to contact us to see how our services can suit your specific requirements and needs!

Welded Beams FAQs

Welded beams are structural components commonly used in construction and engineering. They are created by welding together individual steel plates or sections to form a unified beam. This method offers advantages in terms of strength, customization, and efficiency compared to traditional methods of beam construction.

E beam welding refers to the process of welding an electron beam, while i beam welding refers to the process of welding an I beam. Both methods are used to weld beams, but they have different applications and advantages.

Welded beams come in various types, including:

- H Beams: H-shaped beams are characterised by their wider flanges, which provide greater strength and stability. The welded H beam is commonly used in structural applications.

- W Beams: W-shaped beams, also known as “wide flange beams,” are commonly used in applications where weight-bearing capacity is important.

- T Beams: T-shaped beams are similar to I beams but have a smaller flange width. They are commonly used in building construction and infrastructure projects.

Request a quote

Simply fill out the form or contact us directly on:

Steel Angles

Expertise

Steel Angles

Our attention to structural steel doesn’t end at the corners. Count on strong, stable and twist-resistant steel angles with a clean overall finish.

Steel Angle Suppliers in Sydney

Cedar Steel is capable of overseeing the support for your structure’s corner-bearing loads with made-for-purpose steel angles in Sydney.

Steel Angles

Also known as Structural Steel Angle, L-beam, Angle Iron, or L Steel Angle

L-beams cover and lend support to corners in a building and other structures.

As a structural steel fabricator in Sydney, we have over 30 years of experience in assisting carpenters, builders and business owners with their structural steel needs, including steel angles or L-beams.

We can oversee all aspects of your structural angles, along with your other structural steel requirements with design, advice, fabrication, quality control, speedy delivery and installation.

Get end-to-end solutions to your customised requirements:

- Equal Angles

- Unequal Angles

- Thinner and Thicker Angles

As a fabrication company, we are able to supply angles in the exact dimensions and quantities that you need.

Finishes:

Our fabricators provide equal and unequal angles in Zinc Phosphate Primer to fit Australian industry standards. If you require a different finish, our team can also provide these other options on request:

- Powder Coating

- Hot Dip Galvanised Finish

- Hot Zinc Spray

What is a Structural Steel Angle?

A steel angle is a type of structural steel beam, used for adding strength, support and stability to buildings. Structural angles commonly have an ‘L’ cross-section or shape, by joining together at a perpendicular, 90 degree angle. Similar to other structural steel products they are made through hot-rolling mild steel.

Steel L angles are commonly used for bed frames, box trailers, structures and shelving. Its unique design gives it great bending resistance, in any direction. Similar to other structural steel beams and supports; the larger it is, the more weight it is able to take.

What is an Equal Steel Angle?

Equal steel angles are steel angles with both ends equal in size and thickness.

What is an Unequal Steel Angle?

Unequal steel angles are the opposite. One end of the ‘L-shape’ is shorter, and one end is longer in this design.

Applications for Steel L Angles across industries:

L-beams are often used for framing, shelving, brackets, trims, and reinforcements, among other uses.

For Residential Use:

- Indoor and outdoor structural applications

- Supporting components

- Windows and door frames

- We offer a 48-hour turnaround service for Residential Projects

For Commercial Use:

- Structural Applications and Support Components

- Shelving for Retail

- Offices

- Mezzanine floors to expand retail space

- Manufacturing parts for large steel products such as washing machines or large ovens

For Industrial Use:

- Warehouses and storehouses

- Automotive Manufacturing

- Warehouse Mezzanine Floors

For Civil Use:

- Bridges

Request a quote

Simply fill out the form or contact us directly on:

Steel Channels

Expertise

Steel Channels

Steel channels offer lightweight, flexible structural support for carpentry, masonry and building projects.

Steel Channel Suppliers in Sydney

If you’re in need of steel channels with thorough quality assurance and fast turnaround you can rely on, look no further. We deliver all over Sydney.

Structural Channels

Also known as C-channels, U-channels, J-channels, Z-channels and Parallel Flange channels

Cedar Steel can be your partner in advising, supplying, finishing, delivering and installing the structural steel channels to your specifications to help you complete the structural needs of your building.

As fabricators, we are able to supply steel channels to your customised requirements:

- C Steel Channels

- U Steel Channels

- J Steel Channels

- Z Steel Channels

- Parallel Flange Channels

We are able to supply channels to the exact shapes, lengths, sizes and thicknesses you need.

Finishes:

We supply our structural channels by default, finished in Zinc Phosphate Primer per Australian industry standards.

However, our team can supply other finishes for your project, on request:

- Powder Coating

- Hot Dip Galvanised Finish

- Hot Zinc Spray

What is a Structural Steel Channel?

Steel channels are a type of structure hot rolled from mild steel into a U, J, C or tube shape to provide strength and rigidity to the internal structure of buildings during construction. It is important to get the proportions of these steel products right to ensure that they are safely and securely able to withstand weight and impact from potential loads.

What is a C-channel?

The C-channel, or parallel flange channel, is a shape with a consistent width across the length and thick tapered flanges that give it a ‘c’ cross-section.

Structural C channels were once majorly used to support bridges, but have now become a cost-effective structural component for short and middle-spanning buildings. C-channel beams can be joined together to create a robust box-style foundation, or with a broad flat surface to create an i-beam.

What is a U-channel?

A U steel channel has a similar shape to the C-channel. It has a consistent width across the length of the beam, but with flat parallel flanges instead of tapered ones.

Structural U channels are a common staple in residential use for finishing doorways and window frames.

What is a J-channel?

The J-channel has a longer flange and a shorter flanger, creating its ‘J’ shape. J-channels are also designed for trimming openings on wall panels, doors, windows and louvres to clean up the lines and give the project an overall clean and completed appearance.

What is a Z-channel?

Z steel channels have a ‘z’ shaped cross-section, designed to provide transition and connection to two different materials. They are widely used for metal roofing.

Applications for Steel Channels across industries:

For Residential Use:

- Primary frameworks

- Supporting structural components

- We offer a 48-hour turnaround service for steel channels for Residential Projects

For Commercial Use:

- Retail shops

- Offices

- Mezzanine floors to expand retail space

- Support Components

For Industrial Use:

- Warehouses

- Automotive Manufacturing

- Warehouse Mezzanine Floors

For Civil Use:

- Bridges

Request a quote

Simply fill out the form or contact us directly on:

Universal Columns

Expertise

Universal Columns

Our engineers can fortify your project’s structures with universal columns for maximum strength with vertical loads

Universal Column Suppliers in Sydney

As your partner in structural steel, Cedar Steel will conceptualise, plan, draft, fabricate, and install the universal columns of your building’s structural framework.

Universal Columns (UC)

H-Beams and L-Beams

We can supply to a wide range of requirements for universal columns in Australia:

- Available in 5 basic shapes, flange depths and thicknesses

- Light columns (100mm to 200mm)

- Heavy columns (250mm to 310mm)

Finishes:

Our universal steel columns are finished in Zinc Phosphate Primer as per Australian industry standards.

On request, our team can also supply other finishes to meet your project’s requirements:

- Powder Coating

- Hot Dip Galvanised Finish

- Hot Zinc Spray

What is a Universal Beam?

Universal columns are designed to hold heavy loads along their vertical line and resist twisting.

In comparison, universal beams are designed and used to be spread out to hold loads across the length of the beam. At Cedar Steel, our most popular shapes for universal steel columns are ‘H’ and “L.’

What is a Universal H Column?

These universal columns are known as ‘H beams’ for their ‘H’ shape at the end of their length. This shape gives them strong similarities in width and depth, which makes them an ideal application for projects that require columns with the same strength in both directions to prevent twisting.

The benefits of this shape are:

- Heavier load-bearing capabilities than universal beams

- Efficient at resisting twisting and shear loads

- Supporting floor joists

- Supporting rungs of ladders and stairs

- Supporting mezzanine floors in a warehouse

Please note that while universal columns have better capacity at carrying loads than universal beams, they are also heavier materials.

What is an L-shaped Universal Column?

L shape columns are so named by their corner shape (90 degrees) that makes them look like an ‘L.’ They are mostly used for the corners of boundary walls. L columns provide minor support for structures where strength isn’t critical.

- Resists shear, tension and compression loads in the corners of buildings

- Can be used to anchor flooring to a building’s foundation

Applications for Universal Columns across industries:

For Residential Applications:

- Houses

- Multi-storey dwellings

For Commercial Applications:

- Shopping centres

- Offices

- Retail spaces

For Industrial Applications:

- Mezzanine warehouse floors

- Manufacturing

- Mining infrastructure

For Civil Applications:

- Transport infrastructure

- Bridges

Request a quote

Simply fill out the form or contact us directly on:

Universal Beams

Expertise

Universal Beams

Let us handle the structural steel process in your projects with universal beams that add structure to support heavy loads

Universal Beam Supplier in Sydney

Cedar Steel has the capability to draft, plan, supply, fabricate, install and surface treat universal beams to create durable structures for a range of projects in Sydney

Universal Beams (UB)

Also known as I-Beams or Rolled Steel Joist (RSJ) beams

We can cater to a wide range of requirements for universal beams in Sydney:

- Standard (9m to 20m)

- Heavy (460mm, 540mm and 610mm)

Our team can also produce non-standard beams cut to length in a variety of sizes on request.

Finishes:

All our universal beams are finished in Zinc Phosphate Primer as per Australian industry standards.

However, we can also supply other finishes to meet your requirements:

- Powder Coating

- Hot Dip Galvanised Finish

- Hot Zinc Spray

What is a Universal Beam?

A universal beam is a type of structural steel known for its shape: it has a taller height (the middle section between the side flanges) and shorter flanges (the supporting parts on the ends), with the same cross-section along its length.

When looking at a universal steel beam from either end it looks like a capital ‘I’ in a sans font, which is why it has its name.

The benefits of this shape and its robust composition are:

- High Tensile Strength

- Excellent at bearing load under direct pressure or tension in multiple directions

- More lightweight than Universal Columns (H-Beams)

- Even weight distribution

- Can prevent vibration in a building

Universal beams are often used in conjunction with universal columns to create strong steel structures for buildings.

We provide end-to-end services to look after the steel structure requirements of your project from start to finish.

Undeniably Robust Fabrication

A universal steel beam is always one piece of metal throughout (no welding).

Due to the style of its fabrication (where it is rolled or milled out of steel instead of being joined together by multiple pieces), universal beams are a versatile and dependable structural application for every builder. Making the building of the metal structure process faster and more efficient.

More stable. Less need for numerous structural supports. Less time and money wasted.

Applications for Universal Beams across industries:

For Residential Use:

- Primary Frameworks & Supporting Components

- Residential Dwellings

- Multi-Storey Dwellings

- We offer a 48-hour turnaround time for Residential Projects

For Commercial Use

- Structural Framework

- Support Components

- Shopping Centres

- Offices

- Mezzanine floors to expand retail space

For Industrial Use

- Primary Structural Framework

- Expansions

- Manufacturing

- Warehouse Mezzanine Floors

Request a quote

Simply fill out the form or contact us directly on:

Surface Treatment

Steel Surface Treatment

There are many reasons why a steel surface should be treated. From a purely aesthetic standpoint, it looks more attractive as people walk by your building. But, digging deeper, it protects the steel from scratching and peeling. It keeps the extreme weather in Australia from corroding the metal, keeping its structural integrity.

At Cedar Steel, we offer a variety of metal surface treatments. Steel is usually treated with a zinc phosphate primer, but we can deliver your metal items with several different finishes, meeting the requirements of your project.

Our Range of Steel Surface Treatments

Our standard metal treatment is the zinc phosphate primer, as per industry standard. But we know from experience that different projects require different treatments, so we also use several other methods as requested. Here are the various treatments we use at Cedar Steel and the differences between them.

Zinc Phosphate Primers

Steel beams must be protected to prevent corrosion and wear from the elements. This specially formulated primer is one of the most popular surface hardening treatments available.

Powder Coating

Electrostatic or compressed air is used in this unique method to apply a special powdered coating. This powder is then cured, forming a film over the metal. Then it is dried, creating a hard, durable finish that is extremely resistant to UV rays and rust, and cracking and peeling from the elements.

Hot Dip Galvanised Finish

Another surface treatment process for steel is the galvanised finish. This treatment offers long-lasting protection against all of Australia’s harshest climates. This method can be used for any size or shape of steelwork or metalwork, as it involves sinking the steel into a tub filled with molten zinc. This zinc is heated to temperatures of 450 °C, which then forms a protective coating around the steel. This is another popular option for surface treatment.

Hot Zinc Spray

This option doesn’t allow for quite the same protection as the galvanised steel zinc bath, but it is a popular option because it creates an extremely smooth finish on the steel. In this method, zinc is blasted onto the steel according to specs, usually between 50 and 100 microns. This is a good option for fences and railings.

Whichever method you choose, Cedar Steel will work with you to draw the specs to your requirements and meet the needs you set forth for your steel surface treatments.

Working with Cedar Steel

Cedar Steel has been a leader in the commercial steel fabrication and surface treatment industry for over 30 years. We use our knowledge and experience to provide the best service possible for our customers.

Our goal is to ensure that you get the highest quality steel materials and the best possible steel surface treatments on all of your commercial or residential fabrication projects. If you’re in the market for surface treatments on your next project, give us a call — we’ll get you a free quote.

Expertise

STRUCTURAL POST SUPPLY

QUALITY ASSURANCE

PRE-SITE ASSEMBLY

STRUCTURAL FABRICATION

DETAILED DRAWINGS

INSTALLATION

CUT-TO-SIZE

WELDING

DELIVERY

Expertise

STRUCTURAL POST SUPPLY

STRUCTURAL FABRICATION

CUT-TO-SIZE

QUALITY ASSURANCE

DETAILED DRAWINGS

WELDING

PRE-SITE ASSEMBLY

INSTALLATION

DELIVERY

Frequently Asked Questions

Steel Surface Treatment is the process of modifying the surface of steel to improve its appearance, extend its life and enhance its performance.

This process is done by creating a protective coating that will make the surface of the steel able to prevent corrosion and other forms of damage.

Surface treatment process for steel is recommended because it can extend the steel lifetime and condition as it will protect the surfaces from corrosion, scratching, peeling and extreme weather climates.

Choosing one of the methods of steel treatment will improve the water resistance of steel and upgrade the hardness and sturdiness along with making the steel look more attractive.

The most common method to treat the steel are

Zinc Phosphate Steel:

One of the most popular and recommended, this primer protects and prevents corrosion and wear from elements.

Powder Coating:

This method is done by applying a special coating that then is cured forming a film over the metal, resulting in a hard and durable finish that is very resistant to UV rays and other damages such as cracking and peeling.

Hot Dip Galvanised Steel:

Long-lasting protection against hardest weather conditions and it involves sinking the steel into a tub filled with molten zinc.

Zinc Spray Steel:

Zinc is blasted onto the steel between 50 and 100 microns creating a smooth finish, this method is highly recommended option for fences and railings.

To know what is the best type of method for your steel project, we encourage you to contact one of our professionals that can guide you through.

Cedar steel is dedicated to provide high quality results on every project of steel surface treatment, since we are the top structural steel suppliers in Sydney and throughout NSW with over 30 years of experience.

Cedar Steel is your choice if you need surface treatments, so don’t hesitate to get in touch with us to request a quote and start your next steel project with us.

We also invite you to check all the industries we work with as you need a steel specialist, we are leaders of steel structure fabrication.

Request a quote

Simply fill out the form or contact us directly on:

Structural Steel Fabrication

Expertise

Structural Steel Fabricators

Cedar Steel has worked on a wide range of projects, both big and small, and have the knowledge and expertise with over 25 years of experience in the industry to partner with your residential, commercial and industrial building endeavours.

Structural Steel Fabrication in Sydney

Work with dependable fabricators for all the structural steel supports you need for your residential, commercial and industrial projects. As experts in structural steel design, fabrication, delivery and installation, you can trust us to oversee the entire process.

Cedar Steel has worked on a wide range of projects, both big and small, and have the knowledge and expertise with over 25 years of experience in the industry to partner with your residential, commercial and industrial building endeavours.

Structural steel is one of the most versatile and widely used materials in the construction industry. The strength, durability and lightweight of this material makes it ideal for a variety of applications, from bridges and skyscrapers to smaller projects like sheds and fences. However, on top of getting down the right design and materials, hiring the right structural steel fabricators is essential in ensuring that you get the parts you require for your project, to the precise specifications of your order.

We pride ourselves on our immaculate attention to detail, high-quality workmanship and communicative customer service, so you can be confident that you’re in good hands.

About Our Approach

Structural steel fabrication is a specialised form of steel fabrication that is used to create the framework for buildings and other structures.

At Cedar Steel, we take a holistic approach to structural steel fabrication. We believe that the best way to create high-quality structural steel is to start with the best raw materials and use state-of-the-art manufacturing techniques.

We source our steel plates from reputable suppliers and use advanced computer-controlled equipment to fabricate it to precise specifications. On top of cutting, our fabricators put steel through heat and pressure in the welding process to fold and join parts together. Once complete, we then go the extra mile to protect our structural steel from corrosion by using galvanised coatings and other protective treatments.

The finished product is then shipped to the construction site, where it is bolted or welded into place. As a result of our commitment to quality, we're able to produce structural steel that meets or exceeds the strictest industry standards.

It's why we're one of the leading companies for structural steel fabrication in Sydney.

Structural Steel Fabrication: Our Process

As we comply with all the relevant Australian material and design standards in our steel fabrication services, you can trust us to look after the fabrication of steel structures.

Furthermore, our steel fabricator services is always guided by the needs of our clients: We work with you.

Working off your requirements, we draft designs with full detailed drawings of all the parts you require, erection plans, and clear shop drawings. We can also use 3D drawings for rfi’s, full-scale templates for complex layouts and isometric detail sketches of complex connections to get a full understanding before we start to shape steel, depending on what your project needs. Our metal fabricators then form different structures from pieces of steel through various types of welding that meet the brief you need for your project.

We can offer the following:

- Universal Beams

- Universal Columns

- Parallel Flange Channels

- Tapered Flange Beams

- Channels

- Squares

- Rectangular Hollow Sections

- Circular Hollow Sections

- Flat Bars

- Cleats

- Other Types of Steel Sections

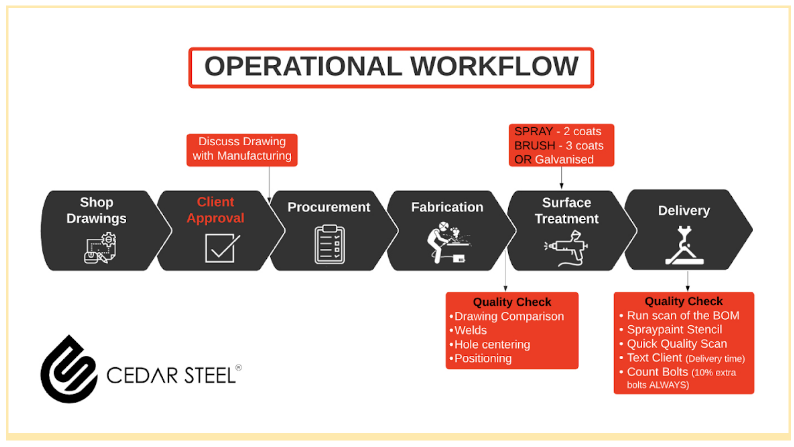

How We Work: Step-by-Step

Shop Drawings - Our draftsman engineers create shop drawings based on initial consultations with our clients. The drawings include important information that can be approved by the client/engineers before installation. Client approval - After discussing the drawings with our manufacturing team, we begin fabrication only after receiving approval from the client. Procurement - We source quality steel (mild steel and industrial steel) in Australia for each job, depending on its unique properties. Fabrication - We start fabricating your project based on the approval of the customer and drawings. We check the quality as we go. When we finish fabricating, we do a test assembly to make sure everything is how it should be. Delivery - We provide all types of surface treatments to increase the longevity and durability of your structural steel beam. Our surface treatments include, and is not limited to, Hot dip galvanising, Weather-Proof Primer, and Zinc Phosphate Priming. Surface treatment - Once our quality checks are done, we deliver the product (with the needed Nuts and Bolts) to your site address. We also provide quality installation services for various steel structures.

Why Choose Cedar Steel?

Structural steel is at the heart of what we do. Our team of structural steel fabricators work with you from start to finish, ensuring your project is delivered on time, on budget, and to the high-quality standards you expect. We have a wide range of structural steel products and services that we offer, and we’re always happy to customise our offerings to meet your specific needs.

Frequently Asked Questions

Structural Steel Detailing is the process of creating detailed drawings and specifications for the fabrication and assembly of steel structures.

Structural Steel Drafting is important because it provides information and details that will ensure that the fabrication and construction drawings of steel are accurate, helping to reduce risk over errors and reworks.

With this process we will make sure the structure is stable and lasting during and over its lifetime as we assure it is under the correct regulations.

3D Steel Detailing works in different stages, first a designer will put into a software – called Computer-Aided-Design (CAD) – the requirements and specifications of the project, this will include every element from the size of the building to the connections details.

Once this is complete, the software generates a 3D model of the structure based on the information provided, the software allows to generate 2D fabrication and erection drawings as it will detailed the information on how the steel structure should be fabricated, assembled and erected on the construction site.

3D technology offers greater accuracy, quality, more flexibility and reduces reworks and errors.

This will depend on the type of steel you need, size and complexity of the project.

In general, structural steel fabrication in Sydney is priced by the tonne, but there are also a number of other factors that can affect the final cost.

For an accurate estimate, it’s always best to discuss your project’s specific requirements with one of our Cedar Steel’s professional members and get a quote.

Cedar Steel is your best choice for a residential, industrial, or commercial steel fabrication.

We are the leading structural steel supplier in Sydney and throughout NSW, as we are experts in what we do with over 30 years of experience in the steel industry.

We are dedicated to providing flexible and personalised solutions in steel. Making every piece unique, we committed to produce all of our projects with the highest quality and under the hands of our dedicated professionals.

We invite you to get to know all the industries we work with and get in touch with us to request a quote to start your next steel project with us.

Request a quote

Simply fill out the form or contact us directly on: