Plasma & Laser Cutting Precision: Robotics Impact

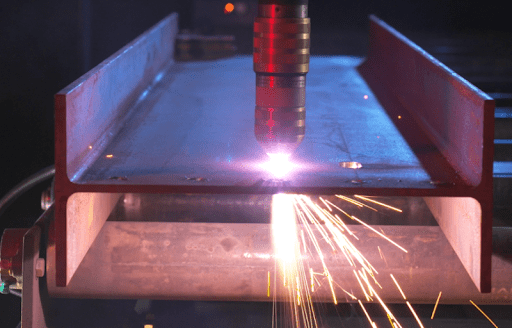

Across Sydney and NSW, steel fabrication is quietly entering a new era. Workshops are moving beyond hand tools and manual setups, adopting smarter, more precise systems that support fabricators. Modern tools like the plasma robot and high-accuracy laser cutters enhance precision, efficiency, and consistency. For Cedar Steel, this shift centres on steel industry automation through two key technologies:

- the X-Calibre robotic plasma cutting machine for beams

- high-accuracy laser cutting for plates

These machines don’t replace fabricators, they support them by delivering speed and accuracy that are difficult to maintain manually, especially on high-volume commercial and industrial projects.

The Current State of Structural Steel Fabrication

Even with automation growing across the industry, structural steel fabrication still relies heavily on people. Fabricators cut beams, drill holes, prep plates, check alignments, and make sure every piece meets engineering requirements.

In metal fabrication, including services like plasma cutting in Sydney, the workload is only getting heavier. Construction timelines are tighter, tolerances are stricter, and structures are more complex than ever. A small slip in a cut, hole spacing, or plate sizing can cause delays once the steel reaches the site.

This is where automation becomes valuable, not by replacing tradespeople, but by taking on the tasks where consistency matters most. Machines designed for precise cutting and drilling reduce rework and keep projects moving, while fabricators focus on layout, quality checks, and project coordination.

Robotic systems replicate accuracy at scale. They don’t lose focus halfway through a long beam or misalign an angle under pressure. And when handled by experienced tradespeople, they multiply output without compromising standards.

What Robotics Bring to the Shop Floor

The biggest change robotics has brought isn’t just speed—it’s steadiness. Robots can handle repetitive tasks, but they also bring calm to the workflow. No rush, no fatigue, no slips in concentration.

For builders and fabricators looking for reliable plasma cutting in Sydney, the X-Calibre system delivers the accuracy and repeatability that modern projects depend on.

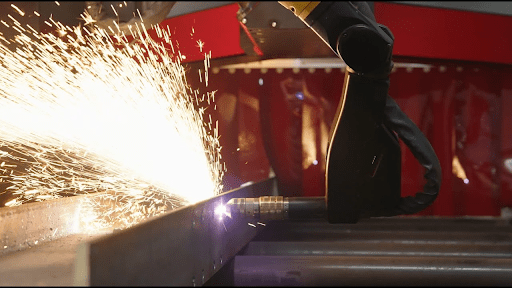

The centrepiece is the X-Calibre robotic plasma cutter, which handles:

- robotic plasma cutting for beams & posts

- robotic drilling and slotting

- complex profiling

- connection detailing with millimetre-level accuracy

Because it follows programmed paths, the X-Calibre cuts and drills beams the same way every time, whether it’s the first part of the day or the hundredth. It removes the guesswork from repetitive tasks and keeps quality consistent.

On the plate side, Cedar Steel uses high-accuracy laser cutting in Sydney. This produces extremely clean, sharp edges with minimal distortion, ideal for plates that need to fit exactly during fabrication or site installation.

The difference on the workshop floor is noticeable:

- smoother workflow

- fewer manual adjustments

- faster turnaround

- more predictable output

Automation becomes a support system for fabricators, not a replacement.

Key Technologies in Steel Fabrication

Every year brings a new layer of innovation in innovative metal fabrication. A few standout technologies are changing how Sydney workshops operate:

- Laser cutting systems capable of slicing complex shapes cleanly, with barely any post-finish work.

- AI metal fabrication software that tracks performance, predicts downtime, and adjusts in real time.

Together, these steel automation technologies turn traditional workshops into adaptive, data-aware spaces, where efficiency isn’t just measured in speed but in accuracy, safety, and reduced waste.

Benefits of the Plasma Machine in Steel Fabrication

1. Precision steel cutting

The plasma system follows programmed cut paths with millimetre accuracy. Beams come off the machine clean, straight, and ready for fabrication, with no drift or variation between batches.

2. Accurate drilling and slotting

Because the X-Calibre can cut, drill, and slot in one automated sequence, connection holes and detailing line up exactly as designed. This reduces rework and eliminates the manual measuring that often introduces errors.

3. Faster throughput

The machine processes beams at a steady pace, regardless of complexity. Cutting and drilling that once took hours by hand can now be completed in significantly less time, helping the workshop stay ahead of project timelines.

4. Consistent quality across large volumes

Whether the team is preparing five beams or fifty, the quality remains the same. This consistency is especially valuable for commercial and industrial projects where hundreds of repeated cuts or hole patterns are required.

5. Safer working conditions

Automating plasma cutting removes the most physically demanding and high-temperature tasks from the manual workflow. Fabricators are exposed to fewer sparks, fewer fumes, and far less repetitive strain.

6. Reduced material waste

Clean, controlled cuts reduce off-cuts and minimise errors that typically lead to scrapped beams. Every piece comes off the machine correctly the first time, offering long-term savings across large projects.

7. Greater flexibility for custom designs

Complex shapes, coping cuts, bevels, and advanced connection details can all be completed directly by the plasma machine without slowing production or requiring secondary processing.

At Cedar Steel Services, the combination of modern tools and experienced people has made a clear difference. Every project benefits from the quiet precision automation brings.

Challenges and Risks

New systems like the X-Calibre aren’t plug-and-play. They require space, operator training, and integration planning. The upfront investment is significant, but the long-term gains in accuracy, productivity, and safety often outweigh the costs.

Across Sydney, more fabricators are realising that automation isn’t a luxury anymore. It’s a practical response to industry demands, labour shortages, and the need for consistent quality.

The human role doesn’t disappear; it changes. Fabricators become programmers, quality controllers, and process supervisors, guiding machines rather than performing every repetitive task manually.

Future Trends in Modern Steel Fabrication

The scale of steel industry automation worldwide shows just how strong this shift has become. As of 2023, over 4.28 million industrial robots were operating across global factories—a 10% increase from the year before, according to the International Federation of Robotics.

Within the metal and machinery industries, robot installations grew 16% in 2024. These numbers reveal what’s already visible in local fabrication—automation isn’t slowing down; it’s accelerating.

Collaborative robots, or cobots, are joining workshops where they share spaces with humans. Predictive monitoring systems now flag issues before breakdowns occur. And AI-driven programs will soon be capable of adjusting weld parameters in real time to match the material’s exact thickness and temperature.

Conclusion

The future of innovative metal fabrication isn’t about replacing the human element, it’s about extending it. Machines provide accuracy; people provide judgment. Together, they build faster and safer than either could alone.

At Cedar Steel, automation is more than an upgrade, it’s part of the company’s evolution. Our latest robotic system adds precision and speed without losing the craftsmanship that defines our work.

That’s the balance the industry is moving toward: technology guided by human experience.

To learn more or start a project with a team blending tradition and progress, browse our steel products, our structural steel fabrication Sydney services or contact our team.